5 COMMON PRINTING PROCESSES

DIGITAL PRINTING

Starting off with one of the most common processes, let’s get techy for a second. Digital printing has two different ways of bringing the ink to life.

INKJET: An inkjet printer produces the image by ink droplets that are fired from the nozzle of one or several print heads. An inkjet is capable of printing on a huge variety of substrates from paper, plastics, canvas, doors, floor tiles, to so much more. This printing is used mainly in posters and signage.

XEROGRAPHY: No one is gonna say “xerography printer”. An xerographic printer is better known as a laser printer. The image is created by selectively applying an electrical charge on a metal cylinder known as a drum. This electrical charge attracts toner particles to the drum. The toner particles are then transferred to the medium that the printer is printing on. To ensure the correct fixation of the toner particles, the substrate goes through a fuser which melts the toner particles into the medium.

Laser printers are mainly used in offices, but they are also used in small run printing for printing books, brochures and other documents. They are also used in transactional printing for printing bills, bank documents, and direct mail.

What did the laser printer say to the sassy inkjet?

Don’t use that… “tone” with me!

OFFSET PRINTING

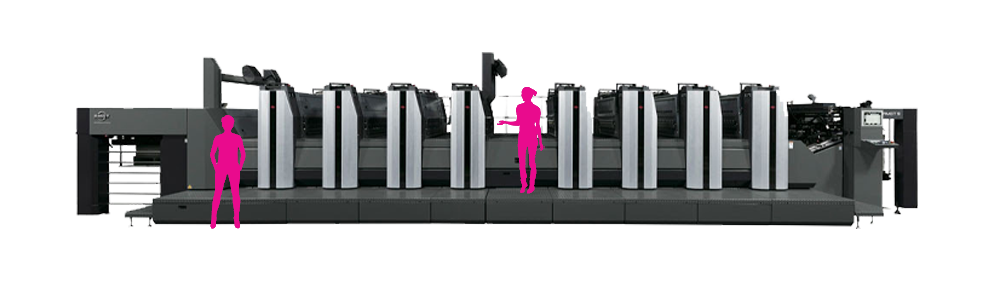

Offset lithography is the process of transferring an (offset) image from an aluminum printing plate to a rubber blanket then to the printed surface. The plate retains the image content and only this part holds ink. Offset lithography can be printed on a variety of materials such as paper, cardboard, and plastic. One important key part to printing successfully is the material must be flat.

These machines are HUGE. Take a look for yourself!

FLEXO PRINTING

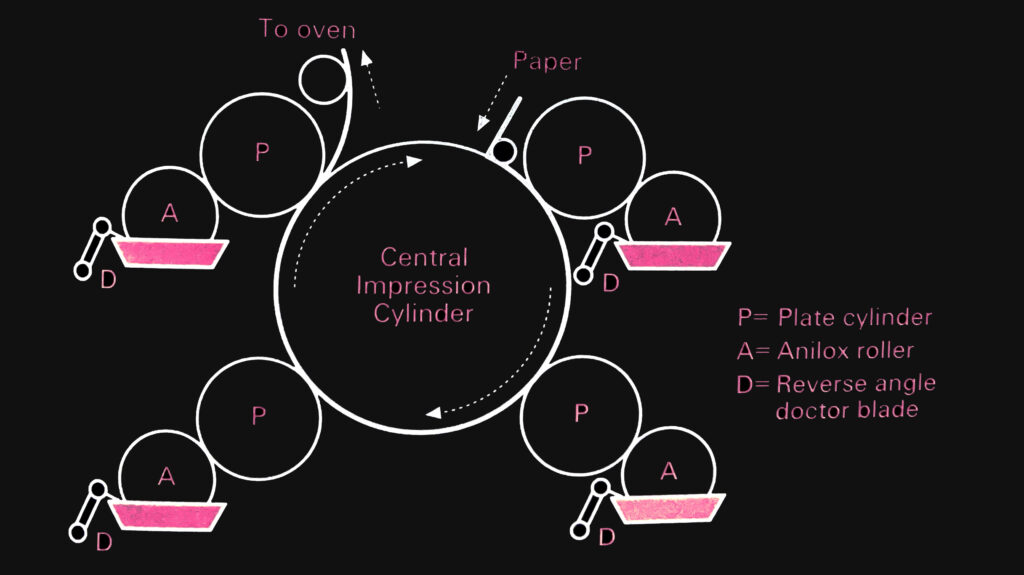

Flexography printing uses a flexible relief plate made of rubber or photopolymer to transfer ink. The content being printed is on a raised surface of the plate. The plate is first inked, and the inked image is then transferred to the printing surface, which can be paper, plastic, metal, cellophane, or other materials.

Flexography is most commonly used for printing packaging, labels, and some newspapers due to its versatility for printing on diverse substrates.

GRAVURE PRINTING

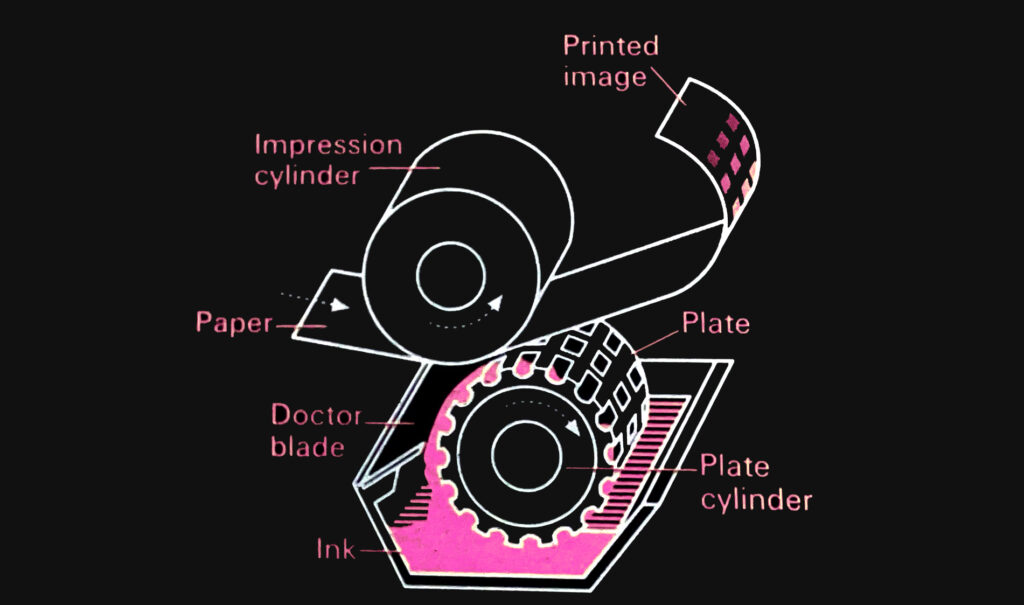

Gravure printing, also known as rotogravure, is a technique in which an image is engraved into a printing cylinder that is then inked and transfers the ink to paper. This high-volume printing method is commonly used for newspapers, magazines, and packaging.

SCREEN PRINTING

Screen printing is something very unique to experience. I actually got the chance to see this in person at a craft show a couple years ago. Right outside of an apparel stop, a huge wheel of spinning screens each are pressed by hand setting in with ink to reveal a perfectly designed t-shirt.

Screen printing uses a woven fabric screen with certain areas coated to prevent ink from passing through. The remaining open mesh allows ink to be pushed onto the printing surface below. Unlike many techniques, screen printing can print on uneven and varied surfaces like textiles, ceramics, wood, and metal, not just flat paper.

SOME NOT SO COMMON PRINTING

Block printing – This technique resembles potato printing, which is a popular pass time for kids. A hand-carved wooden block is inked and pressed on the substrate. Additional blocks can be used to add more colors. Block printing is a slow and laborious process that is still used for printing on fabric in oriental countries.

Flocking – used to add a (colored) velvet-like texture to paper, textiles, etc.

Heat transfer printing – A special paper is printed using inkjet (or another technique) and then this print is transferred to another surface using heat and pressure. The most well-known use case is iron-on decorations for t-shirts but the process is also used for industrial applications.

Intaglio – nowadays mainly used for stamps and paper currency.

Letterpress – This relief printing technique dominated the industry until the early 20th century. Nowadays it is mainly an artisanal process used for upscale business cards and wedding invitations, fine editions of books, limited-run art projects,…

Pad printing – This is also called tampography. An image is transferred from an engraved printing plate onto a three-dimensional surface using a silicone pad. Pad printing is limited to small surfaces and used to print watch dials, gadgets, toys, car parts, etc.

Roller or cylinder printing – Sometimes called machine printing, this is a gravure printing process used for printing on textiles.

Rotary screen printing – This is a very fast printing technique in which ink pours out of the holes of a perforated cylindrical tube directly onto the substrate. This technique only lends itself for printing repetitive patterns and is used for printing wallpaper and textiles.

Thermography – This is more of a finishing process than an actual printing process. It produces raised lettering on the printed side of the paper and is used for wedding invitations, letterheads, and business cards.

PREPRESSURE