WHAT YOU SHOULD KNOW…

BEFORE SIGNING A PRESS CHECK

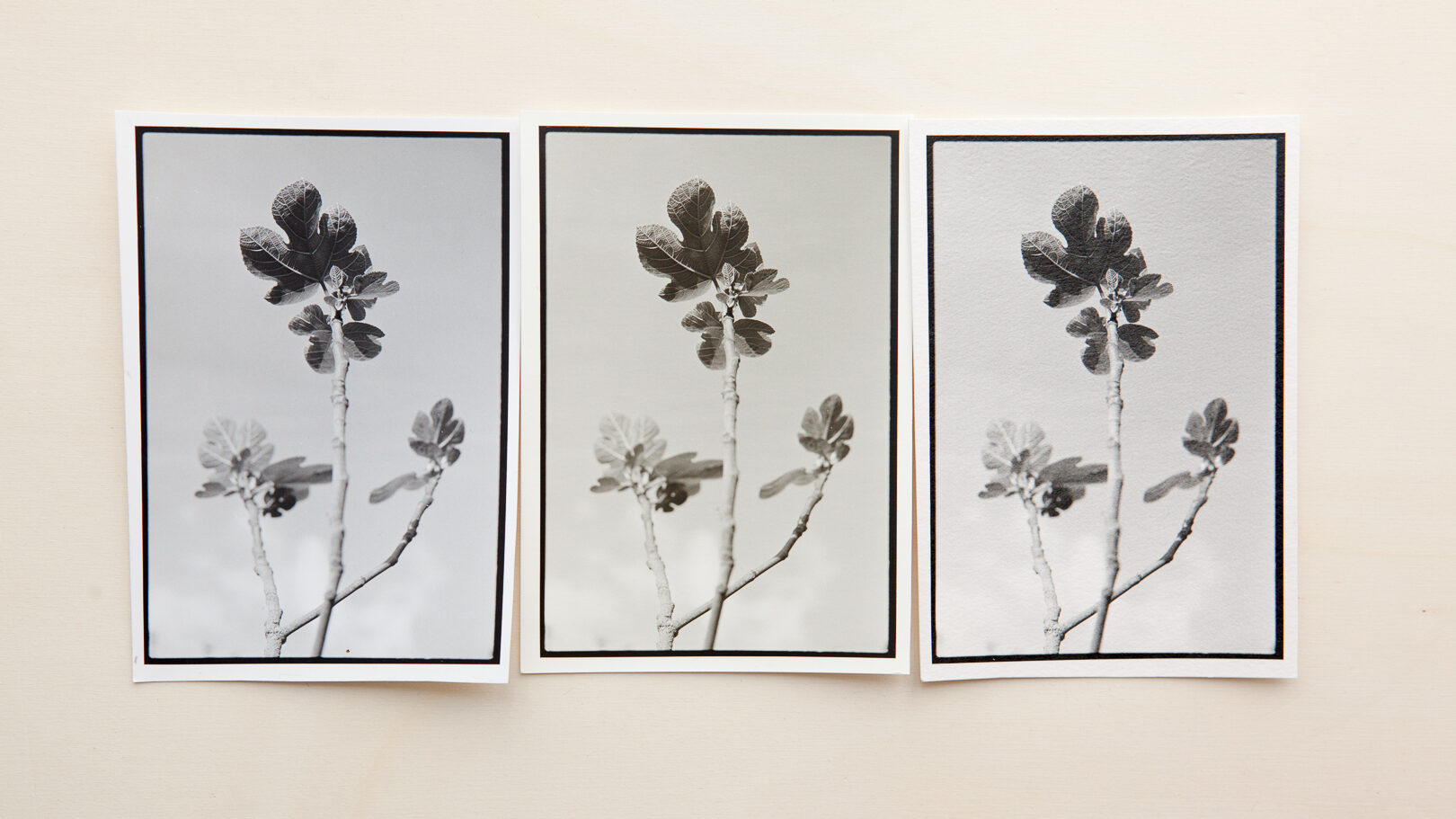

THE PAPER

When printing, it’s important to review your images on the actual paper stock they will be printed on, as the look can vary greatly depending on the paper’s weight, texture, coating, and material.

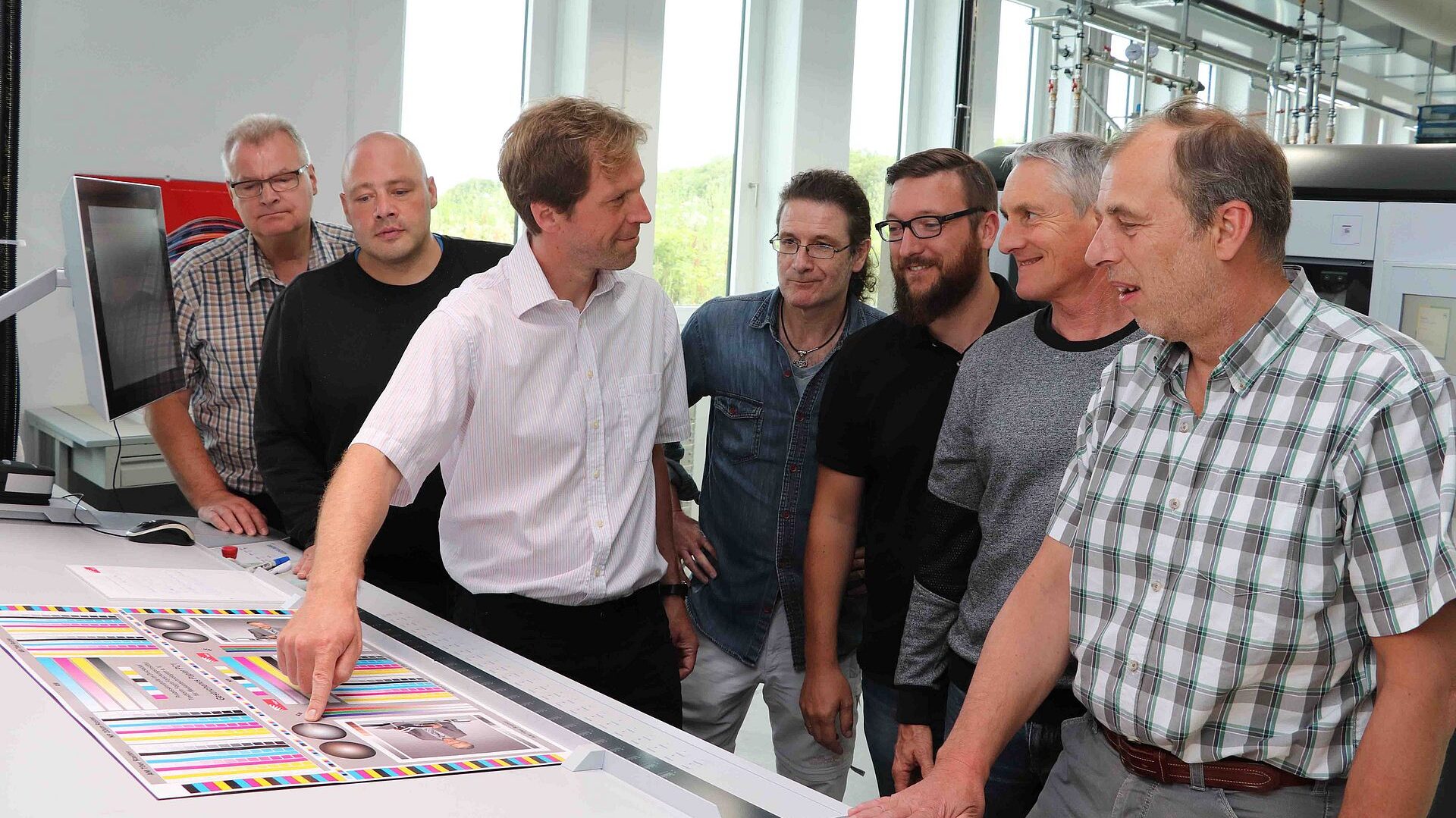

COLOR

When you arrive for the press check, take a step back and assess if the colors on the sheet look visually appealing. Don’t become overly concerned with matching the press sheet and proofs precisely; they should appear similar but don’t need to be identical.

At this stage, you will have already seen high resolution proofs displaying CMYK colors and image resolution.

FLAWS

Hickies were cool when you were 10…but not on the press sheet.

The press operator should scan the press sheet for any unwanted spots, scratches, or marks before the press check begins. Though the press operator typically catches these blemishes beforehand, an extra set of eyes can help ensure quality.

REGISTRATION

Registration marks and crop marks are important for print alignment and cutting alignment during binding.

When you select the option in InDesign to add bleeds and printer’s crop marks when exporting or packaging a file, it inserts these registration and crop marks to facilitate proper alignment.

OVERLAY

Request the overlay proof you reviewed earlier and align it over the press sheet. Confirm everything still matches up correctly. For going off the page, also verify no critical bleed areas were overlooked.

CONSISTENCY

During the press check, feel free to fold the sheet in half to compare colors on the left and right sides. This step isn’t necessary if the colors don’t need to match or if the images differ completely. However, if the colors should be consistent, double check that the press operator has matched the hues on both sides.

COATING

To ensure you are approving the final colors, review the press sheet after the coating has been applied. Coatings can slightly alter colors and how they reflect light. Signing uncoated sheets may lead you to approve colors that will look different once coated. For best accuracy, sign both the ink sheet and the sheet after coating. At minimum, ask the press operator if the coating will affect the appearance of colors and images.

THE PAPER, COLOR, FLAWS, REGISTRATION, OVERLAY, CONSISTENCY, AND COATING

Dave Hopkins

SOME TERMS TO REMEMBER

MAKEREADY

The process of setting up and adjusting a printing press for a particular ink, paper and set of printing conditions prior to a press run. Also, the paper used during these adjustments.

WORK & TURN

To print one side of a sheet of paper, then turn the sheet over from left to right and print the second side. The same gripper and plate are used for printing both sides.

WORK & FLOP

A sheet of paper is fed through the printer, then turned over long ways (below) and fed back through the printer to print on the opposite side.

COLOR BARS

The color strip on proofs that is used as a guide for the printer in determining the amount and density of ink needed.

COVERAGE

The amount of ink on a page or sheet, usually given in percentages.

DENSITY

The amount an object absorbs or reflects light is called “density level.” High-density objects absorb or stop light; low-density objects reflect or transmit light.

PROOF

A prototype of an image that is supposed to show how it will appear when printed on the press.

CROSSOVER

A reproduction that extends across two facing pages in a book or magazine and crosses over the binding.

MOIRE

Objectionable patterns that appear at regular frequencies when two or more screen patterns are placed over one another. May be caused by misalignment, incorrect screen angles, slipping or slurring.

REGISTRATION

The correct positioning of one color over another during the printing process.

PINHOLES

Tiny areas that are not covered by ink.

IMPOSITION

The process of placing graphics into predetermined positions on a press-size sheet of paper. Page layout is the process of defining where repeating elements such as headlines, text, and folios (page numbers) will appear on multiple pages throughout a document, while imposition can be thought of as defining where these completed pages will appear on much larger sheets of paper.

HICKEY

In offset lithography, spots or imperfections in the printing due to dirt on the press, dried ink skin, paper particles, etc.

SCUM

A film of ink printing in the non-image areas of a plate where it should not print.

BROKEN TEXT

A piece of type, whose face has been damaged, and therefore cannot give a complete impression on the surface of the paper.

Printing Industry Midwest

Do not forget…YOU GOT THIS!

FEEL CONFIDENT & SIGN THAT PRESS CHECK